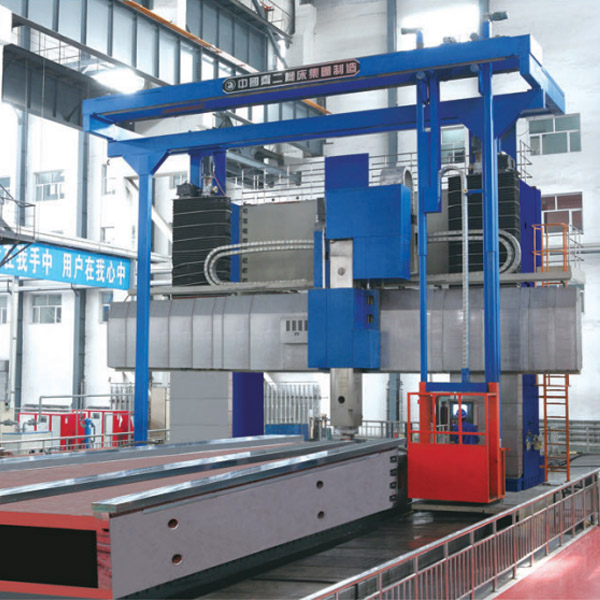

CNC Traveling Bridge Type Boring And Milling 天美直播SERIES XK28/27

Brand QIER WAJI CNC MACHINE

Product origin CHINA LIAONING

Delivery time 3 months

Supply capacity 2-5 units per month

1. Our XK28/27 series of gantry type CNC machines offer advantages such as high speed, high precision, and high rigidity, surpassing comparable machine tools.

2. Our XK28/27 series of gantry type CNC machines are suitable for machining large workpieces and those with complex shapes.

3. Our XK28/27 series of gantry type CNC machines offer high flexibility (variability) and are capable of processing complex processes.

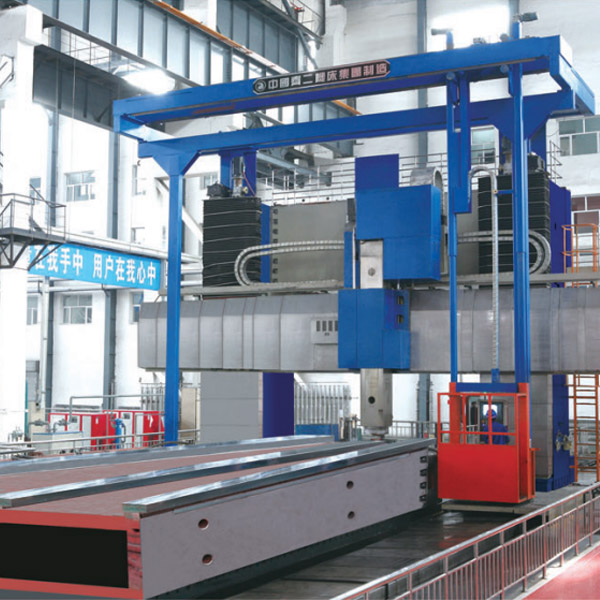

QIER provides remote commissioning and technical guidance for the large bridge mill, allowing you to quickly put it into operation. If necessary, we will dispatch professional after-sales technicians to provide on-site installation and commissioning guidance. (All technicians have at least 5 to 10 years of experience in the industry.)

Our large bridge mill implements strict delivery management and uses shock-resistant and moisture-resistant export packaging to ensure timely delivery.

We also provide a long-term supply of spare parts for the large bridge mill, eliminating the need to worry about subsequent replacement parts.

Introduction of gantry type CNC machine:

Gantry type CNC machines are suitable for rough and fine machining of complex shapes on large machine base parts, large housing parts, and various rotary parts. Gantry type CNC machines are particularly well-suited for machining large precision parts in industries such as shipbuilding, power generation, energy, transportation, mining, metallurgy, and engineering machinery. Furthermore, when equipped with various accessory milling heads, the ram milling head can automatically and continuously perform multi-process, multi-station machining operations, including milling, boring, drilling, reaming, reaming, and tapping, on five surfaces within a single workpiece setup according to a predefined program. Gantry type CNC machine ram boring and milling head can be equipped with a variety of accessory milling heads to expand its processing range.

Features of the CNC walking bridge boring and milling machine:

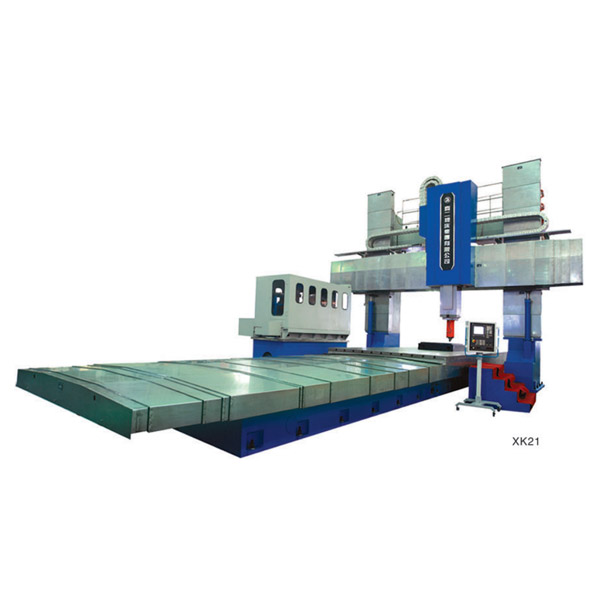

▲ The CNC walking bridge boring and milling machine is available in two types: gantry-type and table-type. Each type can be configured with a fixed beam or an adjustable beam, depending on user requirements.

▲ Users can choose between linear guides (GM series) or hydrostatic guides (XK series) for the CNC walking bridge boring and milling machine based on their processing needs.

▲The main drive features a two-speed continuously variable transmission, delivering high torque at low speeds and constant power at high speeds. This CNC walking bridge boring and milling machine can meet the diverse process requirements of both roughing and finishing.

▲ Equipped with appropriate accessories, the gantry type CNC machine can perform various machining operations, including milling, boring, drilling (drilling, reaming, reaming), and tapping, on multiple workpiece surfaces (excluding mounting surfaces) in a single clamping. This eliminates errors caused by multiple clamping, positioning, zeroing, alignment, and tool setting operations, improving machining accuracy and efficiency.

▲ This fixed gantry CNC mill machine can be configured with a variety of accessories to flexibly meet users' diverse machining needs.

▲ Accessories offer automatic indexing and automatic tool changing functions. Optional tool magazines can also be added to the gantry type CNC machine to enable automatic tool changing.

Specifications of CNC walking bridge boring and milling machine:

Specification/Model | Unite | XK2835/XK2735 | Xk2840/XK2740 | XK2845/XK2745 | XK2850/XK2750 | XK2860/XK2760 | XK2870/XK2770 | XK2880/XK2780 | XK2890 | XK28100 |

Table Size of Large Bridge Mill (W×L) | mm | 2500×8000 | 3000×10000 | 3500×12000 | 4000×15000 | 5000×20000 | 6000×25000 | 7000×25000 | 8000×30000 | 9000×30000 |

Gantry Travel of Large Bridge Mill (Axis X) | mm | 8500 | 10500 | 12500 | 16000 | 21000 | 26000 | 26000 | 31000 | 31000 |

Table Feed Range of Large Bridge Mill (Axis X) | mm/min | 5-10000 | 5-10000 | 5-10000 | 5-8000 | 5-8000 | 5-8000 | 5-8000 | 5-8000 | |

Table Load of Fixed Gantry CNC Mill Machine | Vm2 | 15 | 15 | 15 | 20 | 20 | 20 | 20 | 20 | 20 |

Gantry Frame Width | mm | 3600 | 4000 | 4600 | 5000 | 6000 | 7000 | 8000 | 9000 | 10000 |

Slide Box Travel of Large Bridge Mill (Axis Y) | mm | 4600 | 5200 | 5800 | 6200 | 7200 | 8200 | 9200 | 10200 | 110200 |

Feed Rate of Slide Box (Axis Y) | mm/min | 5-10000 | 5-10000 | 5-10000 | 5-10000 | 5-8000 | 5-8000 | 5-8000 | 5-8000 | 5-8000 |

Cross-Rail Travel (Axis W) (Only For Series XK28 ) | mm | 2000 | 2000 | 2500 | 2500 | 3500 | 4000 | 5000 | 6000 | 6000 |

Feed Rate Of Cross-Rail (Axis W) | mm/min | 1-2000 | 1-2000 | 1-2000 | 1-2000 | 1-2000 | 1-1000 | 1-1000 | 1-1000 | 1-1000 |

Ram Travel of gantry type CNC Machine(Axis Z) | mm | 1250 | 1250 | 1500 | 1500 | 1500 | 2500 | 3000 | 3500 | 4000 |

Feed Rate of Ram (Axis Z) | mm/min | 1-4000 | 1-4000 | 1-4000 | 1-4000 | 1-4000 | 1-3000 | 1-3000 | 1-3000 | 1-3000 |

Ram Section of Large Gantry CNC Machine | mm | 500×500 | 500×500 | 600×600 | 600×600 | 600×600 | 600×600 | 700×700 | 700×700 | 700×700 |

Auto Indexing of Milling Head (Axis C) | 4×90° | 4×90° | 4×90° | 4×90° | 4×90° | 4×90° | 4×90° | 4×90° | 4齿90° | |

Speed Range of Main Spindle(lnfinitely Variable) | r/min | 2-2000 | 2-2000 | 2-1500 | 2-1500 | 2-1500 | 2-1500 | 2-1500 | 2-1500 | 2-1500 |

Main Motor Power of Large Gantry CNC Machine | kw | 37 | 37 | 60 | 100 | 100 | 100 | 100 | 100 | 100 |

What are the differences between the XK28 large bridge mill and the XK27 large bridge millseries?

The XK28 large bridge mill features a movable crossbeam design, with a fixed worktable. The XK28 large bridge mill is more suitable for machining medium- to heavy-duty parts.

The XK27 large bridge mill features a fixed-beam design, with a movable gantry and a fixed worktable. The XK27 large bridge mill is more suitable for machining large, complex parts.

Both mills support five-sided machining, but the XK27 large bridge mill offers superior boring and milling head accessory expansion and an automated clamping system, making it ideal for high-precision, multi-station machining.

Certification of fixed gantry CNC mill machine:

We are certified to the GB/T 19001-2016 / ISO 9001:2015 quality management system. Our production process is controlled, and the quality of our fixed gantry CNC mill machine is stable and reliable, meeting international standards.

FAQ of fixed gantry CNC mill machine:

Q1: What is the maximum machining size of this fixed gantry CNC mill machine?

A1: The machining stroke varies depending on the model of the fixed gantry CNC mill machine. Please send us your specific model number and we will provide you with a response.

Q2: What are the delivery times and after-sales services for large gantry CNC machines?

A2: The delivery time for fixed gantry CNC mill machines is generally 1.5 to 6 months, and we provide installation, commissioning, and training services.

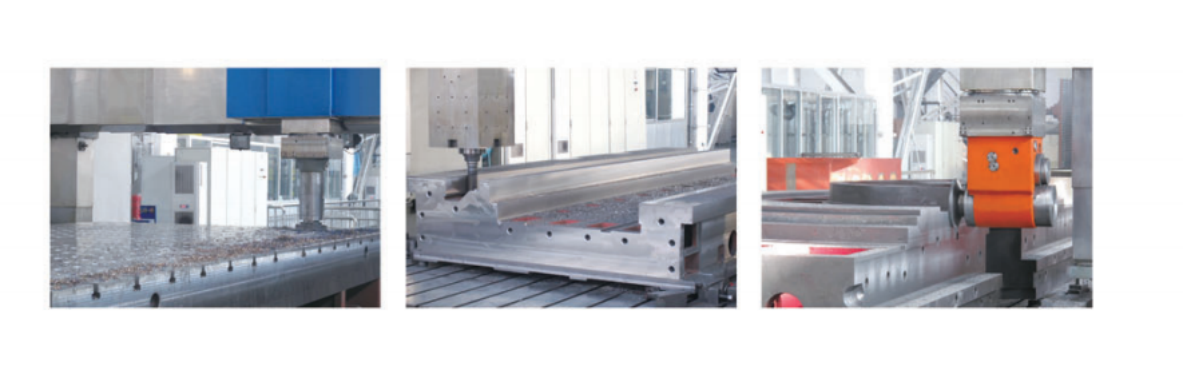

Quality inspection of large gantry CNC machines:

In production, our large gantry CNC machines utilize advanced CNC machining and assembly processes, ensuring precision and stability.

In the inspection phase, the company has established a quality inspection system, requiring all large gantry CNC machines to undergo multiple inspections and trial runs before shipment.

Tips:

Work clothing and goggles must be worn. Do not wear gloves when operating a gantry type CNC machine.

Before starting a CNC walking bridge boring and milling machine, ensure that the tool and workpiece are securely clamped. Do not adjust or measure the workpiece during operation.

Do not clean chips or touch rotating parts while a fixed gantry CNC mill machine is running.

Regularly check the installation of the limit blocks to prevent the worktable from exceeding the range of the large bridge mill.

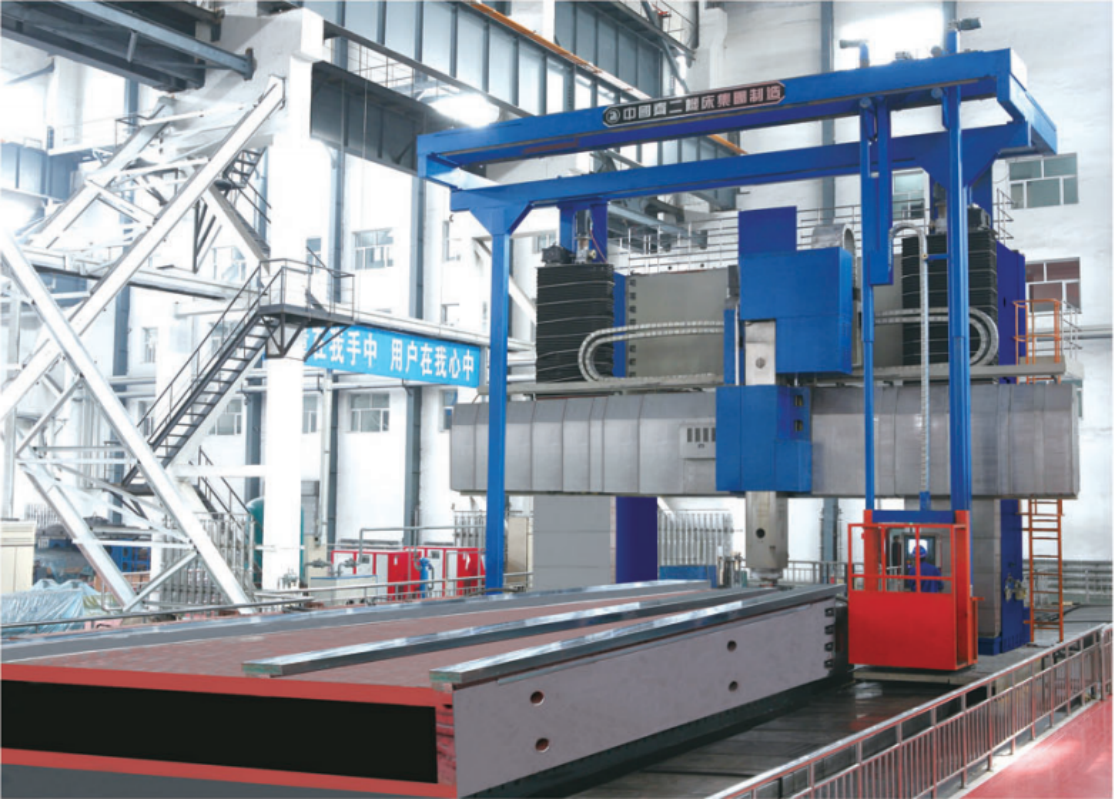

Company profile:

QIER specializes in the research and development and manufacturing of large-scale CNC equipment. Its main products include large gantry CNC machine and other series, and its products are exported to 38 countries and regions.

Our company actively explores the market and meets a wide range of customer needs. To date, we have developed over ten different types of large gantry CNC machines. Our vertical multifunctional large gantry CNC machines, in particular, have replaced similar imported products in China.

Our company has established a nationwide sales network. We honor our commitment to ensuring the quality of our large gantry CNC machines and other products, and we shoulder our responsibilities. We sincerely hope to provide you with the highest quality large gantry CNC machines and the best service at the most competitive prices. We look forward to establishing multi-faceted partnerships with new and old friends around the world and becoming your true partner.